The Technology

In Miracare Meditec, new and innovative methods for manufacturing facial soft tissue prostheses, which prioritizes accurate 3D color image reproduction, have been developed. Also, a framework and protocol for specific 3D processing have been designed. Additionally, color management processing has been developed and successfully applied to 3D imaging devices and manufacturing processes.

Color 3D printing has evolved to produce full-spectrum colored solid objects utilizing a range of materials. With the evolution of various 3D imaging techniques, accurate acquisition and transformation of target object geometric data into 3D digital models can be achieved. By combining the 3D image capture and printing techniques, there is huge potential to reach the goal of “What you see is what you get.” It has the ability to directly interconnect with advanced manufacturing techniques, allowing customization with excellent accuracy resulting in time and costs savings.

There has been huge potential to develop automated additive manufacturing technology for facial prosthetics.

3D Image Acquisition

For face imaging, a laser system combined with a smartphone captures the images. That is, a safe laser line is projected on the subject’s face while the smartphone records the scan process simultaneously.

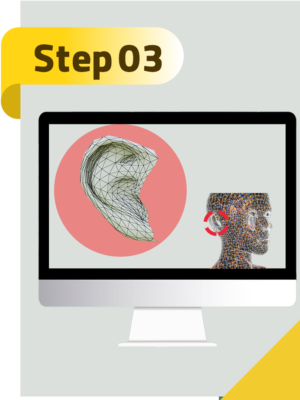

3D Image Reconstruction

The resulted video is imported into our dedicated software comprising the sophisticated and state- of- the- art algorithms developed by our expert AI team. The algorithms are embedded in our exclusive software to reconstruct the 3D model of the face and to create the absent organ that would be substituted.

Missed Organ Modeling

Now, the AI detects and depicts the form and shape of the missing part of the face’s 3D model. The prosthetics 3d model is recreated and rendered in the highest compatibility with the appearance, structure, texture, and color of the user’s natural body skin.

Antibacterial Material

Benefiting cutting-edge knowledge in material sciences, a team of chemists, biologists, and physicians have produced a novel compound with exclusive formulation, to which antimicrobial and antibacterial agents are added. Vital signs diagnosis sensors are imbedded in the final step.

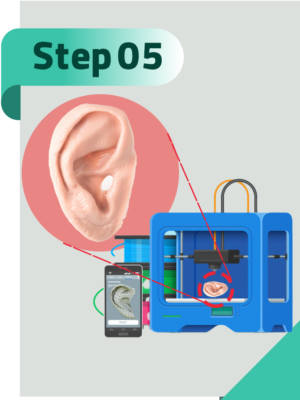

Prosthetic 3D Printing

The final model of the created organ is imported into the specialized 3D printer. Utilizing the engineered antimicrobial and antibacterial materials, the final prosthetic is printed with high and extreme compatibility with the end user’s skin.